In-office production of orthodontic aligners offers many advantages for practitioners. However, the time-consuming and unreproducible manual cutting and polishing of aligners limits production capacity.

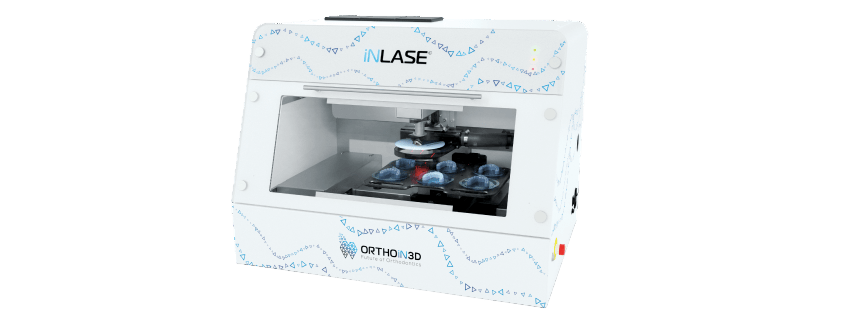

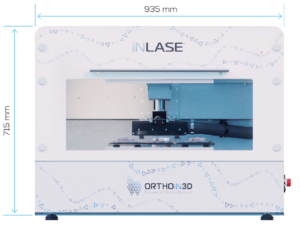

[style_word]iNLase enables orthodontists to unleash their aligner production potential by automating the trimming process.

iNLase integrates perfectly into your in-office production ecosystem, being compatible with all resin printers (DLP, SLA, MSLA etc), all thermoforming systems and most thermoforming plates.

iNLase automatically cuts 6 thermoformed aligners in 20 to 25 seconds per aligner (1), without the need for polishing (2).

iNLase is controlled by iNPLAN (3), our In-Office aligner production management software.

When equipped with iNLase, iNPLAN enables you to generate the semi-automatic cutting line layout for all your models, and the basis for positioning thermoformed models on the machine (4).

(1) Depends on 3D models and cutting line design.

(2) Depends on 3D models and cutting line design. All aligners must be cleaned and decontaminated according to our cleaning protocol.

(3) SaaS software, annual license

(4) iNPLAN is compatible with most setup programs that generate a cutting line (import in .PTS format).

iNLase cuts 6 aligners every 2,5 minutes (1).

Laser cutting produces a smooth surface, without polishing or manual correction (2), maximizing time saved in the manufacturing process.

iNLase can laser-cut up to 1,000 aligners per day.

Every 120 seconds* iNLase cuts 6 new aligners. Laser cutting allows a smooth edge surface without polishing or manual correction**, maximising the time saved on the manufacturing process.

Every 120 seconds* iNLase cuts 6 new aligners. Laser cutting allows a smooth edge surface without polishing or manual correction**, maximising the time saved on the manufacturing process.

Combined with iNLase Software, iNLase allows you to scale in-house aligner production at the pace of the treatment plan.

iNLase can cut up to 1 000 aligners/day.

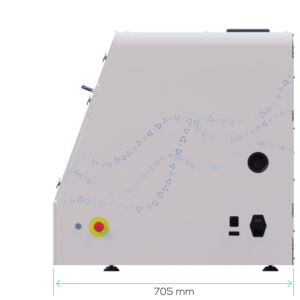

(5) Must be connected to an external air extraction system or directly outside the office or lab.

Download the iNLASE BrochureOrthoiN3D specializes in the support of orthodontists in their strategy of setting up a design and production process of orthodontic aligners in-office.

Leave us a message if you want more information.